A cleaned and polished tyre improves the entire look of your car paint and rims since it adds contrast and depth to the surrounding areas of your car. However, tyre shine sling is an issue that car owners battle with regularly. It occurs when there is excess tyre dressing that gets flung to other parts of your car as it’s driven. This leaves black marks on the wheel and body panels of your car, which can mar your paint in one form or another.

When this happens, most time, car owners blame the product. But is this really the case? Is tyre dressing sling as a result of the product or the application process? Well, while some may argue that the product plays a role, we believe the tyre dressing application must be done properly to avoid a tyre shine sling. In this article, we will look at what causes tyre shine sling and how to avoid it.

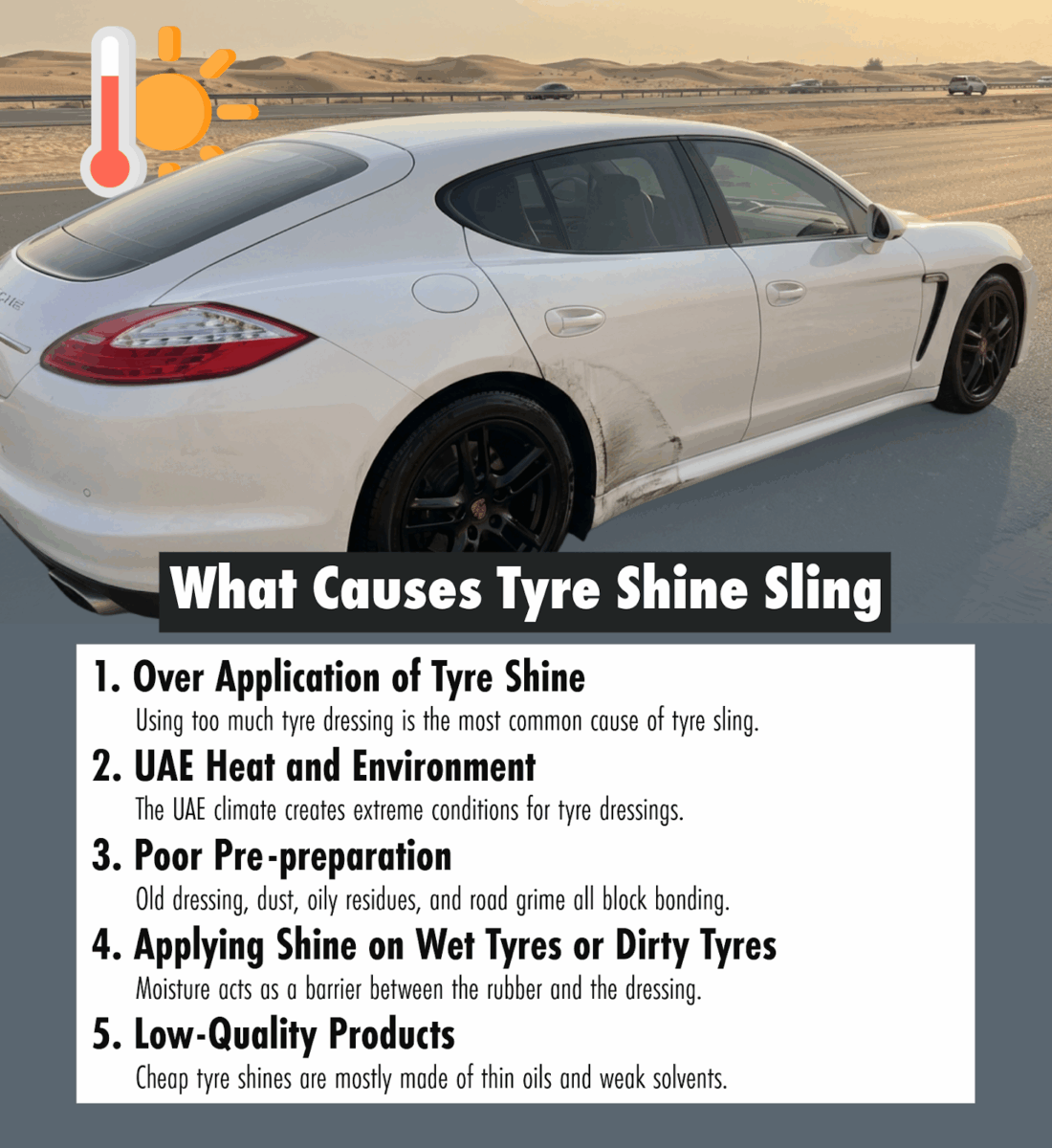

What Causes Tyre Shine Sling

Sling occurs as a result of mechanical and chemical reasons. Below are some of the factors that may cause tyre shine sling:

Over Application of Tyre Shine

Using too much tyre dressing is the most common cause of tyre sling. This is why understanding how to avoid tyre shine sling can help drivers avoid buildup and prevent excess application of dressing. When you apply excess layers on the tyre surface; instead of soaking in or bonding, the extra has nowhere to go, making it stay wet and unstable. As the tyre rotates at high speed, centrifugal force pushes the excess outwards and sends droplets onto the fenders, paint, and lower doors.

Many drivers believe that more dressing gives more shine and durability, but the opposite is the case. Heavy applications stay sticky for longer and never cure properly. It attracts dust and sand, especially in dusty environments like the UAE. When the tyre heats up, the thick layer softens and becomes even more runny, creating a perfect condition for tyre shine sling.

UAE Heat and Environment

The UAE climate creates extreme conditions for tyre dressings. Intense heat thins liquid products and speeds up solvent evaporation. This weakens the dressing before it cures. When a tyre gets hit, even a decent dressing can soften and release residue. UAE hot weather softens and amplifies the sling, especially during highway driving.

UAE sand, dust, and humidity make the whole problem worse. Fine desert sand lifts partially cured dressing while humidity prevents proper drying and allows moisture to sit under the dressing. These factors cause uneven bonding and premature sling.

Poor Pre-preparation

Old dressing, dust, oily residues, and road grime all block bonding. For best results, most of how to avoid tyre shine sling properly involves ensuring the tyre surface is fully cleaned and decontaminated. These contaminants create weak contact points where new product peels or beads and then slings off when the tyre rotates.

Applying Shine on Wet Tyres or Dirty Tyres

Moisture acts as a barrier between the rubber and the dressing. If a product is applied onto a wet surface, the product cannot bond or settle evenly. Instead, it forms beads or streaks on the surface that dry more slowly and detach as the car moves, causing a sling. Dirt also blocks proper adhesion and creates uneven patches.

When contaminants remain on the tyre wall, the dressing tries to sit on top of them rather than on the rubber. This contact leads to poor durability and early shedding.

Low-Quality Products

Cheap tyre shines are mostly made of thin oils and weak solvents. These formulas give a quick, glossy look but fail to bond properly. They stay wet and slippery for a long time, because they do not cure into a durable layer. As a result, they fling off easily once the tyre begins to spin.

Higher-quality solutions, on the other hand, use silicone polymers or advanced gel formulas. These materials hold onto the runner and resist slinging because they create a stronger bond. It is important to note that due to the hot climate in the UAE, inferior products melt, drip, and soften once exposed for long under the UAE’s harsh sun. This leads to streaking, patchy gloss, and heavy sling.

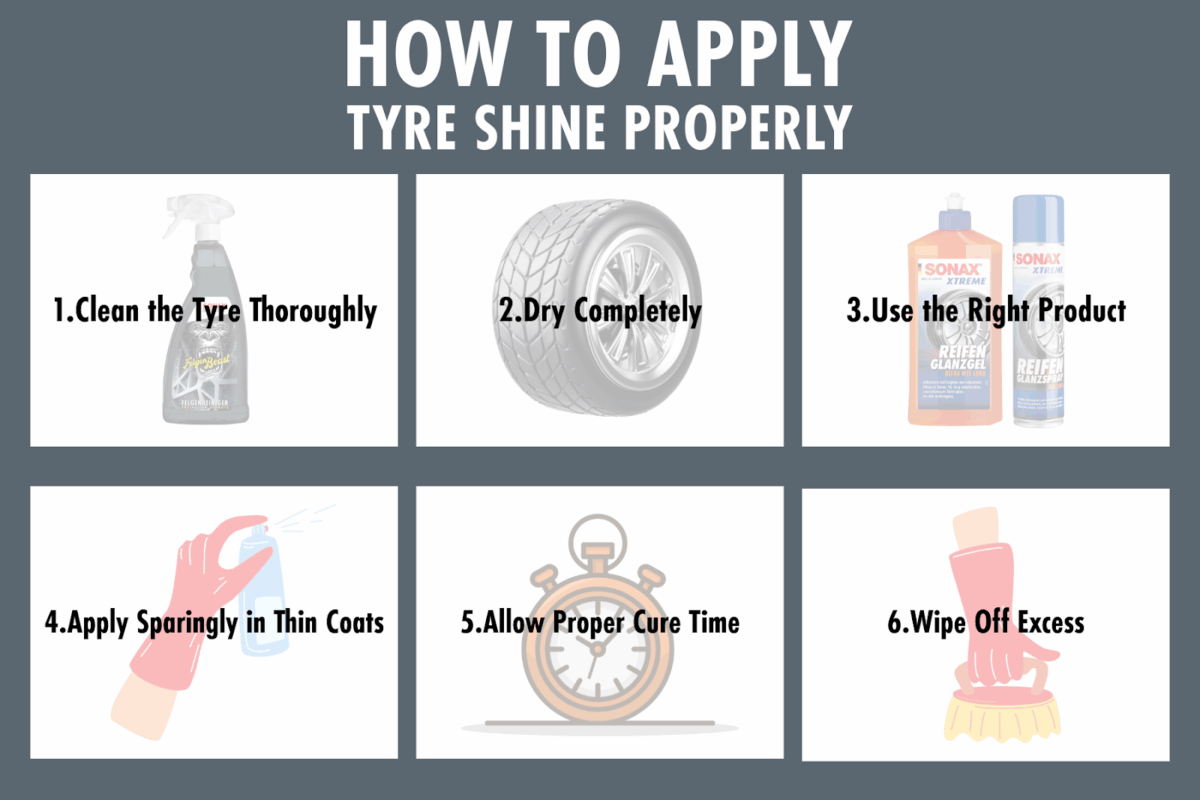

How to Apply Tyre Shine Properly

To get the best results from tyre shine, you must first know the proper way to apply it. Below is a detailed guide that helps you achieve the best tyre shine application.

Clean the Tyre Thoroughly

A proper tyre shine always begins with a clean surface. Use soap, an all-purpose cleaner, or a dedicated tyre cleaner from Sonax to scrub with a stiff brush to remove old dressing, brake dust, and dirt.

A clean tyre also gives the dressing a strong base to bond. Residual chemicals weaken the bond between the dressing and rubber. Rinse thoroughly to ensure no cleaner remains on the tyre. This improves the shine, durability, and evenness of the finish.

Dry Completely

Tyre dressing does not bind properly to wet surfaces. Water creates separation and causes beading, which leads to tyre shine sling once the car starts moving. Use a microfiber towel or allow the tyre to air-dry fully. Before applying the dressing, check the grooves and lettering where water often hides. Dry tyres also prevent streaks and patchy gloss.

In the humid UAE conditions, drying tyres properly entails allowing extra drying time to make sure the rubber is fully ready. Also, you can use a blower to remove trapped water.

Use the Right Product

Choose a high-quality dressing with heat-resistant polymers. Gel-based or advanced silicone polymer dressing binds better and slings less. They stay stable under the UAE’s harsh temperatures and do not melt easily. Avoid ultra-cheap sprays that rely on oily solvents, as they tend to sling heavily once exposed to the UAE’s hot weather.

Read product labels to get products made for hot climates. Many new formulas are designed to handle UV exposure and temperature swings. They last longer and produce a more uniform finish. It is also essential to buy high-quality tyres.

Apply Sparingly in Thin Coats

A thin layer allows the dressing to penetrate and bind evenly. Thick layers, on the other hand, sit on top of the tyre and remain wet after the application. Use a small amount of the product on a foam applicator and spread evenly across the sidewall of the tyre. This is to make sure the product enters the rubber instead of leaving a shiny puddle.

Allow Proper Cure Time

Every tyre dressing needs time to settle and dry. Most products cure in 10-30minutes. Heat may also speed up or slow down this process, depending on the formula, which is why it’s very important to read the product’s label carefully. It is always advisable to let the tyre sit in the shade during curing, as sunlight accelerates evaporation but does not help bonding.

Wipe Off Excess

After curing, carefully inspect the tyre for wet spots or uneven areas. Removing this excess is a key part of how to avoid tyre shine sling properly, even in the sandy UAE conditions. Use a clean microfiber to remove leftover product, as excess dressing is the main cause of sling.

Removing extra products also prevents dust and sand from sticking. This final wipe-off step is a major part of clean, safe tyre shine application.

Best SONAX Products to Avoid Sling

Choosing the best tyre shine UAE offers not just for the gloss shine but also for superior bonding and heat resistance for daily driving. Here’s a close look at some of the best Sonax products for this purpose:

Sonax Profiline The Gloss Gel

Sonax Profiline Tyre Gloss Gel is widely regarded as one of the best UAE tyre dressings if your goal is a long-lasting, glossy finish with minimal sling. Its gel formula penetrates and conditions the rubber while delivering a deep black wet look. If applied correctly, it doesn’t leave a loose, runny layer that’s likely to fling off when the tyre spins.

Sonax Tyre Care (spray/ standard tyre gloss)

If you prefer something quicker and easier than a gel for lighter maintenance, the Sonax XTREME Tyre Gloss Spray is a viable option. When using spray, it is important to note that because they have lower viscosity than gels and are more fluid, spray dressings are more prone to tyre shine sling, especially if applied heavily or unevenly.

Maintenance Tips for UAE Drivers

Driving in the UAE exposes vehicles to extreme heat, intense UV, fine sand, and a very hot road surface frequently. These conditions accelerate tyre and exterior wear, change how products behave, and also affect how long a tyre dressing or sealant needs to bond before you drive.

How Often to Clean and Reapply Tyre Dressing

These tyre care tips help vehicle owners maintain clean, conditioned rubber under the region’s extreme weather conditions.

- Weekly visual checks/monthly maintenance for high-use cars: Proper cleaning plays a big role in successful tyre shine application because dirt blocks bonding. Inspect tyres weekly for embedded sand/grit, cracking, or surface dulling. For cars driven daily, plan a full clean and dressing every 3-4 weeks.

- Sessional/heat-adjusted rhythm: During the UAE’s hottest months (May-September), expect shorter effective lifetimes for cosmetic dressings. Plan for reapplication at the shorter end of the range, let’s say 2-4 weeks, while in cooler months, you can stretch to 4-8 weeks depending on product durability.

Heat Specific Advice (Product Behaviour, Timing, and Tyre Health)

It is vital to note that you should never apply dressing on a hot tyre surface or in direct midday sun. Hot tyre surfaces change the viscosity of dressing, prevent proper bonding, and increase the risk of sling once you drive.

Published regional data and studies show asphalt in the UAE can exceed 60°C on peak summer days. These surface temperatures heat tyres quickly and affect application and cure time. Apply early in the morning, late in the evening, or in shaded areas or garaged spaces.

Go for viscous gel or polymer-based waterborne dressings for hot climates as they have high heat tolerance and adhere better than runnier, oil sprays. Gels are easier to apply thinly and buff; this lowers the risk of sling in hot conditions. Following these tyre care tips ensures your dressing bonds properly even during the hottest months.

Drying and Cure Time Before Driving

Proper tyre shine application includes allowing the product enough time to bond before exposing the tyre to heat or high-speed driving. The time needed for the product to cure depends heavily on the weather; hotter periods require more time. You can inspect the drying of your tyre shine by lightly pressing a clean black microfiber to the sidewall. If it picks up a measurable product, buff again, and wait.

A minimum of 20-30 minutes wait is expected after your final buff before driving, but in hot, humid, sandy conditions, a 30-60 minutes wait is highly recommended.

Conclusion

A well-maintained tyre is one of the simplest but most influential factors in keeping your car clean, safe, and visually sharp. After reviewing the best tyre shine and correct maintenance habits, a few themes stand out clearly. It’s clear that product choice matters. When you use the right products like Sonax Tyre cleaner, Sonax Tyre gloss gel, or Sonax Tyre Care, they drastically reduce the likelihood of slinging and extend overall tyre health.

It is also worth knowing the best tyre care tips, like a proper application method determines the final results and effectiveness of the dressing. Even premium products perform poorly if applied on hot tyres, in direct sunlight, or if applied without properly cleaning the surface. Shop SONAX’s Tyre & Wheel Care Range.

FAQs

Tyre shine sling happens as a result of excess product or unbonded residue flying off the tyre as you drive your car. It occurs when too much dressing is applied to the tyre, especially after applying the dressing to a dirty surface, or when you do not let the dressing cure properly before driving, or when you use cheap products.

You are expected to wait at least 20-30 minutes after applying tyre shine. But in very hot UAE temperatures, the ideal wait period is between 30-60 minutes.

Yes, UAE heat directly increases the risk of tyre shine sling. Tyre surfaces get extremely hot due to temperatures that may exceed 60°C, and hot rubber causes tyre dressing to thin out and reduce bonding.

For the cleanest finish with the lowest sling-risk finish, use thick gel dressings or high-quality water-based polymer products. These products provide a long-lasting solution compared to sprays and they are perfect for avoiding tyre shine sling.

As a beginner, you just have to ensure the surface is properly cleaned, dried before applying the product (use an applicator, not directly to the tyre). Use thin coats and buff excess after 3-5 minutes. Never apply directly under the sun or on a hot tyre and leave to cure for 30-60 minutes before driving your car.